TOLERANCE ANALYSIS

Defining how fabrication and machining tolerances affect the performance of an optical system are crucial metrics in most optical engineering efforts. Seattle Photonics has a large amount of experience defining and analyzing tolerances for a wide variety of systems. The optical and mechanical tolerances of the components that go into an optical system are usually balanced in terms of several parameters: performance, component cost, ease of assembly, and optical compensators. Likewise, the tolerances can be matched against performance characteristics of concern such as the MTF of the optics, the spot sizes produced, the uniformity of an illuminated field or the distortion induced by the optics. SPA also works with our preferred component vendors, or our clients vendors to properly define these tolerances during fabrication.

Defining how fabrication and machining tolerances affect the performance of an optical system are crucial metrics in most optical engineering efforts. Seattle Photonics has a large amount of experience defining and analyzing tolerances for a wide variety of systems. The optical and mechanical tolerances of the components that go into an optical system are usually balanced in terms of several parameters: performance, component cost, ease of assembly, and optical compensators. Likewise, the tolerances can be matched against performance characteristics of concern such as the MTF of the optics, the spot sizes produced, the uniformity of an illuminated field or the distortion induced by the optics. SPA also works with our preferred component vendors, or our clients vendors to properly define these tolerances during fabrication.

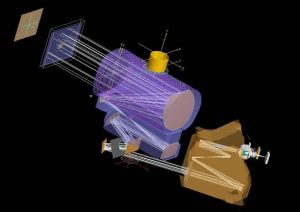

A few examples of occasions when Seattle Photonics was brought in to supply tolerance analysis for a client include the following:

- SPA helped determine the amount of permissible deformation of a 1 meter primary that allowed for a less then 0.2% relative illumination in the far-field.

- SPA also helped another client determine the tolerances associated with an Earth observing optical system that allowed channel to channel distortion differences of less then 1%